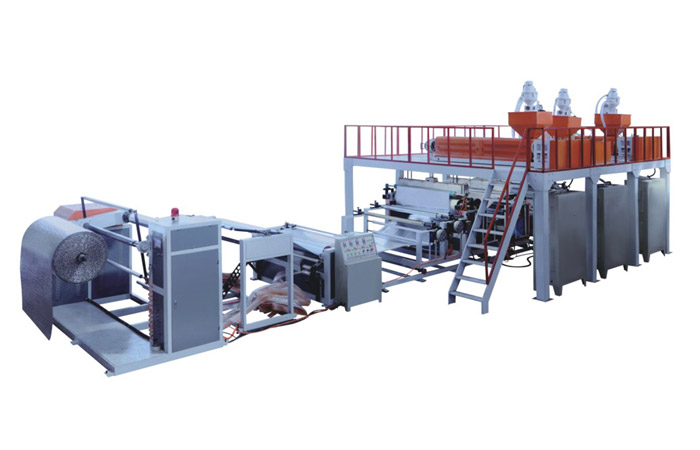

Summary

It is applied to air bubble film of LDPE and LLDPE. The machine can produce Max 7 layers(5 layers +2 layers PET aluminum foil), laminates Kraft paper, EPE foam, PET aluminum plating film, PE film and other products, By changing the bubble mold roller to change the diameter of bubble φ 6-30mm, products are water proof, pressure proof,antistatic, insulation and so on. widely used in fumiture, hard ware, building materials, electronics, courier and other packaging industry.

Characteristic

Optional Equipment 1.Chille 2.Automatic Feeder/Loader 3.Auto Changing Sieve 4.Blender 5.Scrap Reverse 6.Grinder 7.Auto Cutting Rewinding 8.In-line perforated unit

Sample

technical parameter

| Model | Screw mm |

Width mm |

Production kg/h |

Power kw |

Screw L:D |

|

CXPEC-3000 |

φ90/80/80/90/80 |

3000 | 350 | 280 | 32:1 |

|

CXPEC-2500 |

φ85/75/75/85/75 |

2500 | 260 | 250 |

32:1 |

|

CXPEC-2000 |

φ75/65/65/75/65 |

2000 | 220 | 200 |

32:1 |

|

CXPEC-1800 |

φ85/70/85 |

1800 | 180 | 160 |

32:1 |

|

CXPEC-1600 |

φ80/60/80 |

1600 | 140 | 150 |

32:1 |

|

CXPEC-1500 |

φ75/55/75 |

1500 | 140 | 150 |

32:1 |

|

CXPEC-1200 |

φ70/55/70 |

1200 | 100 | 110 |

32:1 |